MVQ

Symbol: MVQ / VMQ

Common name: silicone rubber, high molecular organosilicon polymers

Trade name: Silicone, Silopren®, Silastic®, Elastosil®, Ecosil®, Silplus®

What are its characteristics?

The most important properties of silicone rubber are:

- ⇒ excellent thermal and heat stability – up to do 200°C, and even to 300°C for short periods of time

- ⇒ very good elasticity in low temperatures

- ⇒ excellent resistance to weather conditions, aging and ozone

- ⇒ very good resistance to oils and hydraulic fluids

- ⇒ very good resistance to UV and gamma radiation

- ⇒ resistance to oils and fats of plant and animal origin

- ⇒ water (max. up to +100°C)

- ⇒ resistance to motor and gear aliphatic oils

- ⇒ good electric isolation properties

- ⇒ high gas permeability

- ⇒ non-flammability

The term silicone depicts a wide range of materials with poly-organosilicones with a high molecular weight, as its central element. Silicones are quite unusual among synthetic rubbers, as they are partially organic, and partially nonorganic. In chemical terms their main chain consists of siloxanes, depending on the type, vinyl, methyl, trifluoropropylic and phenylic groups on polymer chains.

Silicone rubbers are built on a nonorganic Si-O chain structure with organic side groups. They are created through the polymerization of chlorosilanes, e.g. methylchlorosilanes. Depending on the molecular weight they can form:

- crosslinked high-temperature solid rubber (HTV type)

- rubbers with texture from paste-like to solid, crosslinked with various additives, which also cure when treated with heat (LSR – Liquid Silicone Rubber)

- crosslinked in normal temperature (RTV), among which we can distinguish one-component and two-component crosslinked polymers

Organic side chains are mostly built of methyl groups. If the primary chain has only methylic side groups, it is marked as MQ. When some additional vinyl groups are added to the structure, the system carries the abbreviation VMQ. When a phenylic group is added – it is PVMQ, and if there aren’t any vinyl groups – PMQ.

How does the structure of side groups influence the polymers properties?

- Vinyl groups improve the degree of crosslinking and the behavior after deformation pressure stops operating, and also values of breaking strength.

- Phenylic groups improve properties in low temperatures and resistance to high-energy radiation.

Usage

Silicone rubber is used in:

- ⇒ electronic industry

- ⇒ electric industry

- ⇒ household goods

- ⇒ printing

- ⇒ glass industry

- ⇒ construction industry

- ⇒ automotive industry

- ⇒ railway industry

- ⇒ medical industry

- ⇒ food industry

Such rubbers have excellent dielectric and anti-adhesive properties, but also low toxicity and that is why they may be used in many ways for food and medical purposes, as they do not add flavor or odor.

In comparison with conventional rubber, their tensile strength is quite low (<15MPa), similar to their tear strength. They are moderately resistant to mineral oils (depending on their class) and fuels, and are characterized by slight permanent deformations while pressing. But on the other hand, they show great resilience to fats and oils of animal and plant origin, break oil and motor oil.

Their huge advantage is also a wide range of operating temperatures.

Silicone rubber is non-flammable and has good dielectric properties. Low tear strength and low abrasion resistance, narrow down the possibilities of use in dynamic conditions.

Typical curing is based on peroxides. Lately, elastomers with polyaddition crosslinking have been introduced. They are characterized by being easy to process and they do not leave any unpleasant smell, typical for peroxides.

With silicone rubbers it is possible to create mixtures with a hardness range from 20 to 80ºShA. Silicone mixtures can be processed through all methods typical for the rubber industry, that are used to produce technical products for some of the most popular recipients, like motorisation, electronics and electrotechnology, medicine, food industry, aeronautics, construction.

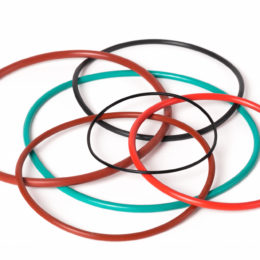

Sealing ring, O-ring, membranes, cable insulations, electrical connectors, hoses, sanitary ware and surgical instruments are among the most common products.

Silicone can be modified to be electrically resistant, conductive or flame retardant. Many silicone compounds are characterized by mould shrinkage that is more significant than normal. That is why, production moulds for silicone products are different from those for nitrile.

Vulcanizates do not adhere to sticky surfaces or ice, because they are hydrophobic. Thanks to special products improving adhesion, silicone rubber may permanently bond with metals, glass, textiles, etc.